How Important is the Method of Galvanizing to Service Life?

The service life of an MSE structure depends on the select backfill environment and the method of galvanizing the soil reinforcements. As per the AASHTO LRFD Specifications, metallic soil reinforcement and connection hardware shall be galvanized in accordance with AASHTO M111 (ASTM A-123). The specified method, referred to as Hot-Dip Galvanizing, is essential for the long term service life of the structure, and it is the coating method on which the AASHTO corrosion loss model is based. Use of Sheet Galvanizing or Mechanical Plating for MSE soil reinforcements and/or connection hardware is NOT in accordance with the AASHTO specifications and is NOT recommended as these methods will result in a reduced service life of the structure.

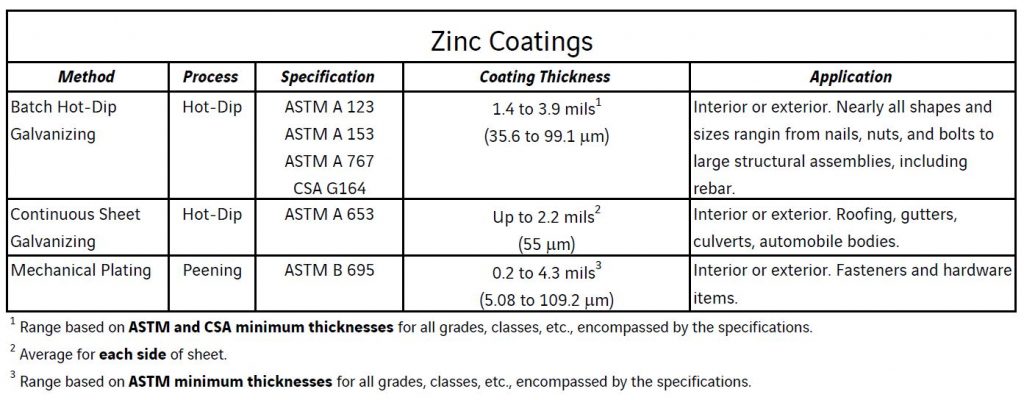

There are several zinc coatings commercially available, each having unique characteristics that determine their applicability and service life. Many people use “galvanizing” as a generic term for all types of zinc coatings. They are not all the same, in fact, their physical, chemical, and corrosion resistant characteristics differ. Three of the most popular zinc coatings are discussed below.

Hot-Dip Galvanizing

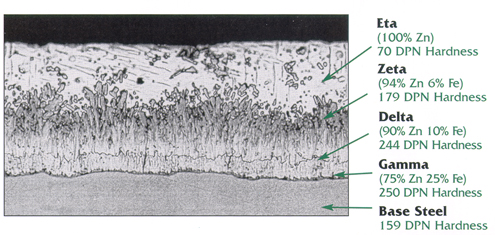

The most common and widely used coating method to protect steel from corrosion is batch hot-dip galvanizing. Steel is cleaned by either mechanical or chemical means and then immersed in a molten bath of zinc to form the coating which is comprised of zinc-iron alloy layers and an outer layer of pure zinc. The coating actually becomes part of the steel’s surface due to the metallurgical reaction that occurs when iron in the steel reacts with molten zinc to form the alloy layers. These alloy layers can be clearly seen in the micrograph in Figure 1.

Since the alloys that form are harder than the base steel, they provide good abrasion resistance and are the basis for the toughness of the galvanized coating itself. The bond strength of the alloy layers to the steel is approximately 3600 psi. Since the layers grow perpendicular to the surface of the steel during immersion, a uniform coating forms on all surfaces including corners, edges, and threads. Coating thickness depends on the type of material being galvanized but a coating thickness of about 5 mils (128 microns) will form on ¼” thick material.

Sheet Galvanizing

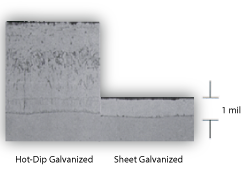

This process is similar to batch hot-dip galvanizing in terms of cleaning and immersion in molten zinc. However, this process is limited to sheet steel in coil form that is subsequently unwound and passed through the galvanizing process at speeds up to 500 feet-per-minute and is then recoiled at the end of the production line. A comparison of coating thickness between continuous galvanizing and batch hot-dip galvanizing is shown in Figure 2.

The alloy layers found in hot-dip galvanized coatings are also present in sheet galvanized coatings but the coating thickness is generally much thinner with the continuous process. Since service life is directly proportional to the coating thickness, continuous sheet galvanized coatings are not suitable for MSE soil reinforcements and connection hardware. Two typical classifications for sheet galvanized coatings are G60 and G90 with average coating thicknesses of about 0.5 mils (13 microns) and 0.75 mils (19 microns) respectively.

In addition, slitting of galvanized coil to fabricate soil reinforcements and connection hardware will produce product with black, uncoated edges, which will further reduce the effectiveness of the coating.

Mechanical Piping

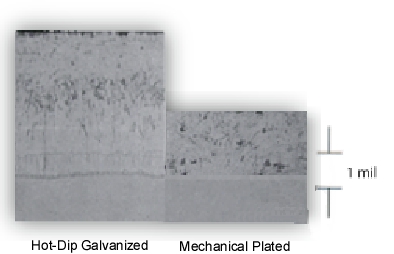

For this process, steel parts are cleaned and placed in a drum with proprietary chemicals, zinc powder and glass beads. The drum is tumbled until the desired zinc coating thickness is peened onto the parts by the glass beads. The process is limited to small parts that will fit in the drum and they must be of simple design. Complex designs may not be thoroughly coated due to inaccessibility of the plating chemicals and glass beads. The average coating thickness on commercial fasteners is about 2 mils (50 microns). A comparison of coating thickness between mechanical plating and batch hot-dip galvanizing is shown in Figure 3.

It should also be noted that mechanical plating results in a zinc density that is only 70% of the density of zinc when coated by hot-dip galvanizing, i.e., 30% less zinc is provided for the same coating thickness. In addition, the inter-metallic alloy layers are absent, and therefore the bond strength of the coating is considerably weaker, on the order of several hundred psi instead of 3600 psi.

Each of the coating processes described above have merit in certain applications. However, as per the AASHTO Specifications, only batch hot-dip galvanizing shall be used for protection of soil reinforcement and connection hardware in MSE structures.

Tap to Call

Tap to Call Tap to Email

Tap to Email