Building Retaining Walls on a Curve

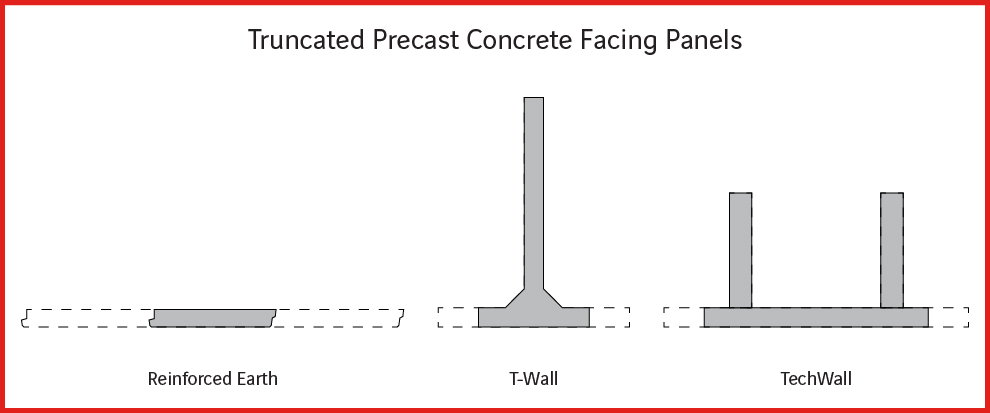

Retaining walls that use precast concrete modular facing – such as Reinforced Earth®, T-Wall®, and TechWall™ – can accommodate curved and spiraled horizontal alignments with a radius of less than 30 feet. Small radii are commonly used for pedestrian bridge and trail applications.

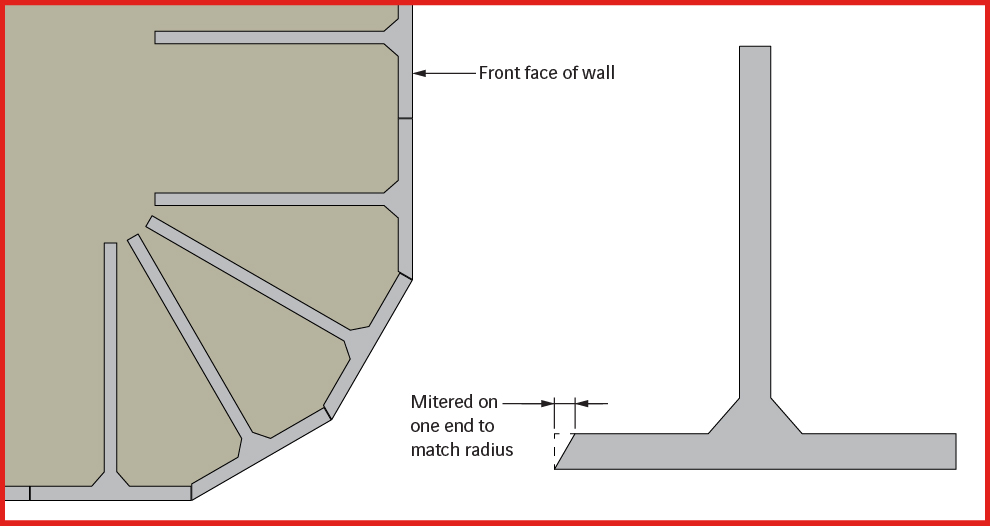

The individual facing panels are not curved, but the curvature of the wall is formed by a series of short chords, depending on the width of the panels.

Examples of curved retaining walls:

Curve tolerance for conventional walls:

Without altering construction methods, nor providing special design of the precast facing, RECo’s retaining wall systems can accommodate an outside or inside radius as low as:

- 50 feet for 5-ft x 5-ft Cruciform or Square Reinforced Earth and GeoMega MSE panels

- 50 feet for 5-ft wide standard T-Wall panels

- 80 feet for 7.5-ft wide large T-Wall panels

- 85 feet for 8-ft wide standard TechWall panels

- 100 feet for 5-ft x 10-ft Rectangular Reinforced Earth and GeoMega MSE panels

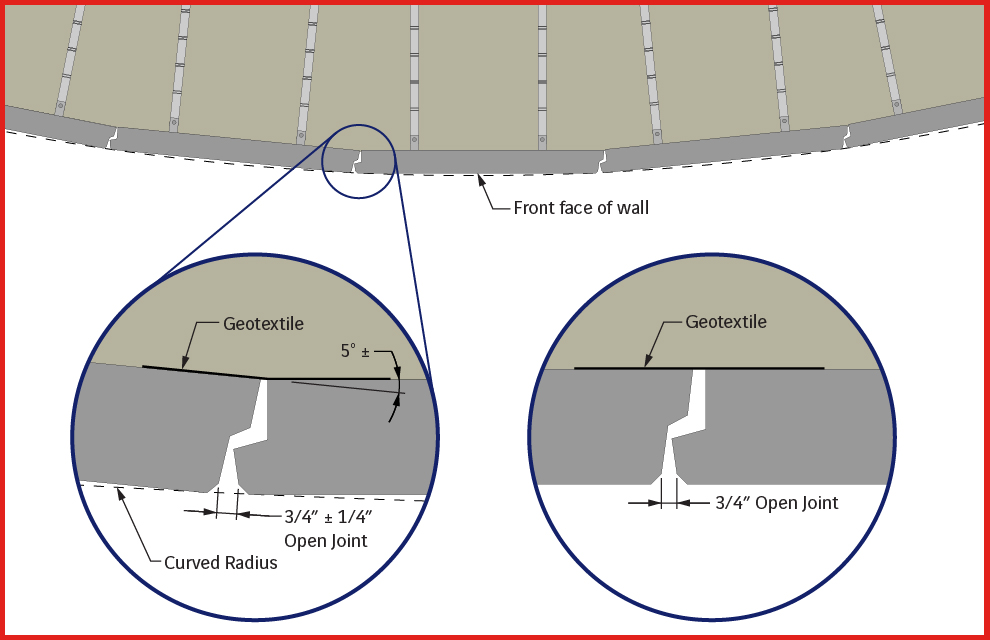

The minimum radius is typically limited by the allowable bend between two panels, which is controlled by the recommended tolerance of the open vertical joint size. Reinforced Earth MSE panels include ship-lap joints.

MSE walls with wire mesh facing do not have open joints between panels. Wire mesh facing can generally be cut and bent in the field to closely fit wall curvature per the design.

Accommodating tighter curves:

To design for a curve smaller than the above limitations, simple modifications to the facing panels and construction methods can be made. Solutions include:

Truncated width panels:

MSE wall panels can be cast to widths as small as one foot if necessary. MSE walls on a radius of less than 50 feet should be constructed using square or rectangular panels, which have continuous full-height vertical joints, as opposed to cruciform panels, which have a non-linear vertical joint.

T-Wall units can be formed with the facing truncated on either side of the stem to reduce the width of the facing.

TechWall units can be cast narrower than the standard 8 feet width. Depending on the shortened width, only one counterfort may be needed per panel.

Mitered ends:

The facing panels on each wall system can be mitered on the ends to allow for a larger angle between panels, while maintaining the proper vertical open joint size tolerance.

Additional joint material:

The typical vertical joint between RECo’s precast retaining wall panels requires only a layer of geotextile on the back face to prevent migration of backfill through the joints. Particularly for inside or concave curved walls, as well as panels without a ship-lap joint, wider joints can be treated with additional joint material such as:

- A second layer of geotextile

- Joint filler such as backer-rod or foam

- A small piece of concrete behind the joint, called a back-up panel

Questions?

MSE retaining walls, and other wall types with modular facing have the versatility to fit a variety of geometry that may be required on a project. Wall curvature formed with precast concrete or wire mesh panels is easily achievable with the proper considerations. Contact us if you’d like any assistance in planning your project.

Tap to Call

Tap to Call Tap to Email

Tap to Email