Mechanically Stabilized Earth (MSE) Retaining Walls

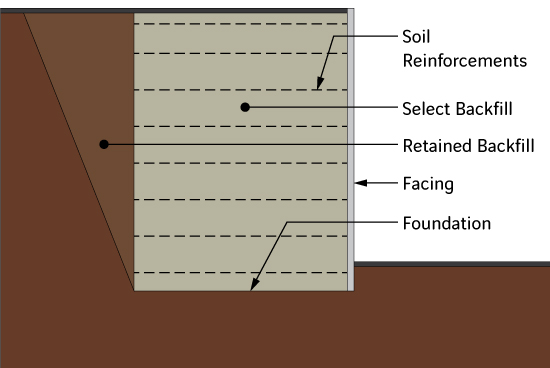

A Mechanically Stabilized Earth (MSE) retaining wall is a composite structure consisting of alternating layers of compacted backfill and soil reinforcement elements, fixed to a wall facing.

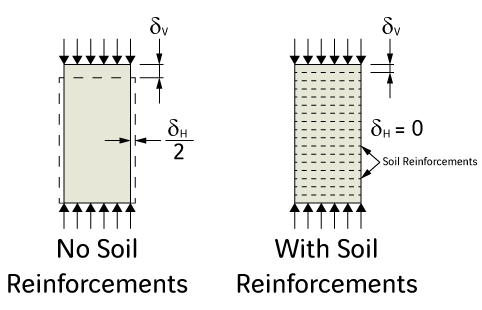

The wall facing is relatively thin, with the primary function of preventing erosion of the structural backfill. Soil retaining walls are designed to bring stability to natural slopes in construction projects. Stabilization for MSE retaining walls comes from the interaction between the backfill and soil reinforcements, involving friction and tension. The wall facing is relatively thin, with the primary function of preventing erosion of the structural backfill. The result is a coherent gravity structure that is flexible, stable and can carry a variety of heavy loads.

The properties and materials of the three major components can vary, and a mechanically stabilized earth engineer must choose the most efficient combination of construction materials based on the wall’s design criteria, such as wall height and service life. Each of these elements works together to create a stabilized retaining wall.

Facing elements are modular precast concrete panels or wire mesh. Each facing type offers different advantages when considering criteria such as aesthetics, durability, construction procedure, and expected settlement.

Soil reinforcements are typically steel or geosynthetic, in the form of strips or ladders. All soil reinforcement options have unique characteristics for pullout and tensile capacity, corrosion, and durability.

Select backfill allows for reliable construction and performance of the wall, in which the gradation, plasticity, electrochemical properties, and overall durability should be closely analyzed. It can be obtained on site, or from a distributor.

Benefits of MSE Walls:

- Flexibility to accommodate high differential settlement and several feet of total settlement

- Bearing pressure is distributed over a wide foundation area

- Extreme wall heights can be achieved

- Extreme loads can be carried (bridge abutment footings, cranes)

- High resistance to seismic ground movement and other dynamic forces

- Free-draining, due to granular backfill and open panel joints

- Form liners or elaborate murals can customize the aesthetics

- Soil reinforcing strips can easily accommodate obstructions within the MSE backfill volume

- Very versatile. Special design can allow for nearly any geometry

- Rapid, predictable, and repetitive construction

- Superior finished wall alignment

- Mechanical connection of soil reinforcements to facing units

Facing Elements

Choosing the right facing type depends on the application, aesthetics, differential settlement, service life, and other factors.

Concrete panels:

- Shapes:

- RECo’s trademark Cruciform

- Rectangular

- Square

- Sloped

- Full height

- Integrated with Traffic Barrier

- Custom

- Thickness varies as needed for architectural finishes, walls with extreme heights, or other applications yielding high bending moments

- Embedded connections for soil reinforcements

Wire mesh panels and baskets:

- Galvanized or black steel

- Temporary or permanent wall applications

- Additional accessories for soil reinforcement connections

Soil Reinforcements

RECo’s soil reinforcements have gone through extensive full-scale testing for pullout capacity, tensile capacity, durability, and corrosion. They have been engineered flat to achieve superior and predictable bond with the compacted backfill, having no potential for voids between the soil and reinforcement.

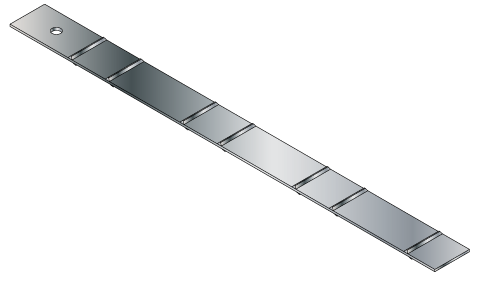

High-Adherence (HA) Ribbed Reinforcing Strips

- Inextensible

- 2″ wide

- Galvanized steel

- High tensile and pullout capacity

- Ideal for most applications

- Bolted connection to facing elements

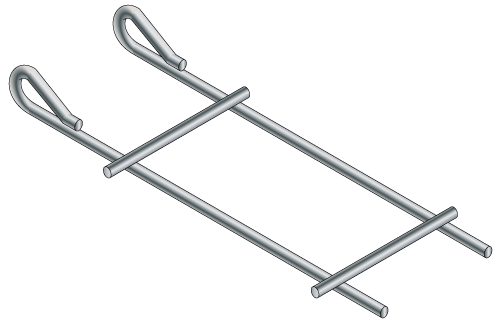

High-Adherence Ladders

- Inextensible

- 4″ wide (transverse bars)

- Galvanized steel

- Higher pullout capacity and reduced tensile capacity

- Ideal for short height walls, or with lightweight or low strength backfill

- Bolted connection to facing elements

Retained Earth® Two-Wire Wide Ladders

- Inextensible

- 9″ wide (transverse bars)

- Galvanized steel

- Higher pullout capacity and reduced tensile capacity

- Ideal for short height walls, or with lightweight or low strength backfill

- Clevis loop connection to facing elements

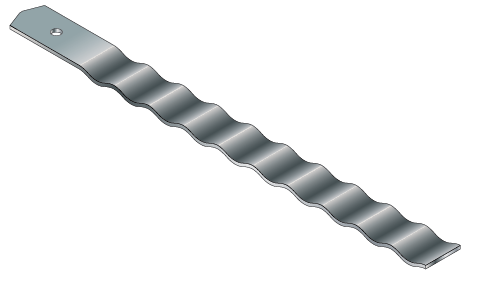

Sine Wall® Reinforcing Strips

- Inextensible

- 1.5″ to 2.5″ wide

- Galvanized steel

- High tensile and pullout capacity

- Bolted connection to facing elements

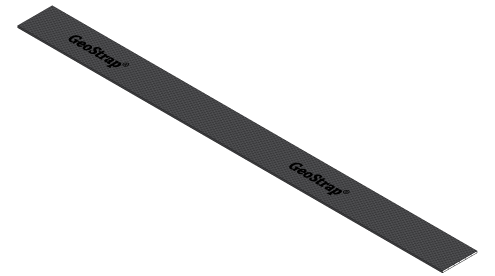

GeoStrap® Geosynthetic Reinforcing Strips

- Extensible

- 2″ wide

- Polyester fibers in a Polyethylene sheath

- High tensile and pullout capacity

- Ideal for highly corrosive environments

- Sleeve or wrapped connection to facing elements

Select Backfill

- Soil

- A wide range of soil properties will meet specifications, however the ideal select backfill is open-graded with low plasticity and fines content, such as sand or crushed stone. This allows for easy compaction and fast drainage.

- Recycled

- Crushed concrete and other recycled material can be used successfully as MSE select backfill.

- Lightweight

- In cases where the MSE wall must have a significantly reduced load on the foundation, lightweight material can be used such as lightweight aggregate, low density cellular concrete, and foamed glass aggregate.

Contact Us Today!

Let’s discuss your next geotechnical engineering construction project.

Tap to Call

Tap to Call Tap to Email

Tap to Email