Precast Arches by Reinforced Earth

The engineering benefits of arches have been known for thousands of years, and explored most famously by the ancient Roman Empire. Materials and methods of design have evolved over the years, but the basic principles have remained the same.

The overburden load is carried along the arch from the top down to both ends, in pure compression, with zero or minimal tension in the arch member. It allows for a very efficient design of the arch span, and use of materials that typically do not have a high tensile capacity.

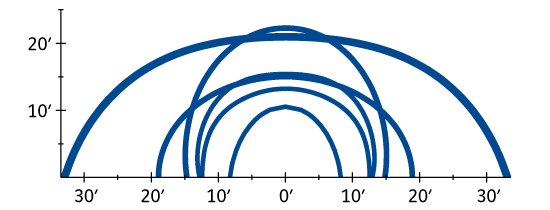

RECo’s arch product, TechSpan®, exhibits this efficiency in design and construction. Using reinforced precast concrete and a catalog of proven optimized shapes, RECo’s engineers design and manufacture the arch units based on the project’s loading and clearance requirements.

With accompanying retaining walls, the result is substantial load-carrying ability with minimal materials that provide efficient high-performance bridges, tunnels and other proven solutions for applications in roadways, railway, mining, military, and beyond.

Applications of TechSpan Precast Arches include:

- Short to medium span bridges

- Tunnels for roadway, railway, pedestrian, and mining site reclaim or access

- Culverts

- Ammunition storage facilities

- Above ground earth shelters

TechSpan Precast Arches

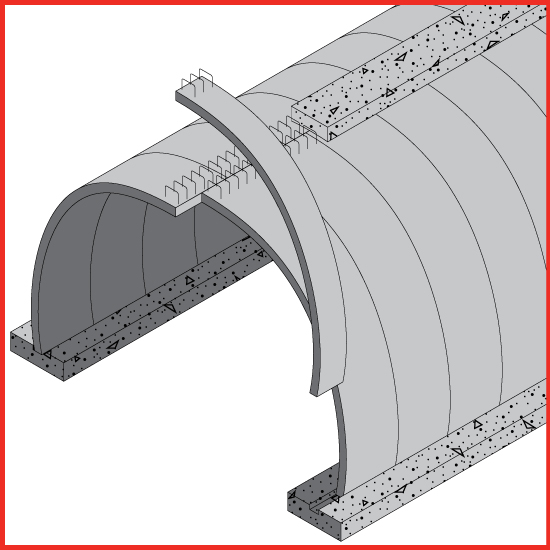

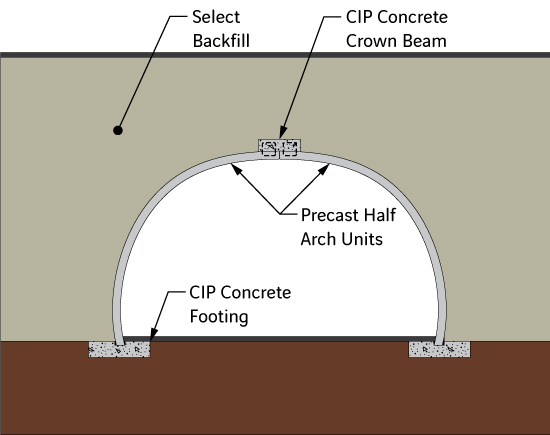

TechSpan is a three-hinged precast concrete arch system, consisting of half arch units that meet at the crown, supported by precast or cast-in-place footings sized for site specific conditions. MSE walls are easily customized and built at the ends of the arch tunnel, forming a standalone bridge, concrete tunnel, or hydraulic structure. The arch units are typically eight to ten inches thick, and are custom designed for the application to minimize materials.

TechSpan construction starts with the installation of cast-in-place or precast footings on both sides. The arch units are set and grouted along the footing keyway in a staggered pattern. After the third unit is set, the arches are self-supported during the remainder construction. Geotextile or geomembrane is applied to the joints as designed. The crown beam is cast along the top of the arch, locking both sides together. MSE headwalls or wing walls are then installed as designed.

Benefits of TechSpan Precast Arches:

- Finite element design provides for the development of the optimal shape based on loading conditions.

- Precast segmental arch units simplify shipping, delivery and installation.

- Self-supporting unit design and installation procedure minimizes heavy equipment usage and bracing requirements.

- Precast units are manufactured under strict quality control environments and tolerances to insure ease of installation.

- Capable of supporting large surcharges in excess of 100 feet.

Tap to Call

Tap to Call Tap to Email

Tap to Email