Electrochemical Corrosion Tests for MSE Backfill

In addition to measuring strength properties for MSE wall select backfill, electrochemical tests must be performed to determine the soil’s corrosivity when using steel soil reinforcements. The AASHTO design model for MSE wall soil reinforcements is based on sacrificial thickness, meaning, metal loss is expected to occur and the reinforcements must have adequate steel remaining at the end of the service life to safely carry the design load. Soil properties that control corrosivity, and their AASHTO-specified values and test methods:

- Resistivity

- Requirement: ≥ 3000 Ohm-cm

- Test Method: AASHTO T 288

- pH

- Requirement: 5 to 10

- Test Method: AASHTO T 289

- Sulfate Content

- Requirement: ≤ 200 ppm

- Test Method: AASHTO T 290

- Chloride Content

- Requirement: ≤ 100 ppm

- Test Method: AASHTO T 291

The Role of Resistivity

Resistivity is the measure of the soil’s ability to resist the flow of electrical current. For corrosion to occur, an electrical current must flow in the soil, so the higher the resistivity, the lower the corrosion rate. As a result of extensive field and laboratory studies spanning nearly 40 years, the sacrificial thickness has been determined based on the soil having a minimum resistivity of 3000 ohm-cm at 100% saturation.

Resistivity Testing using AASHTO T 288

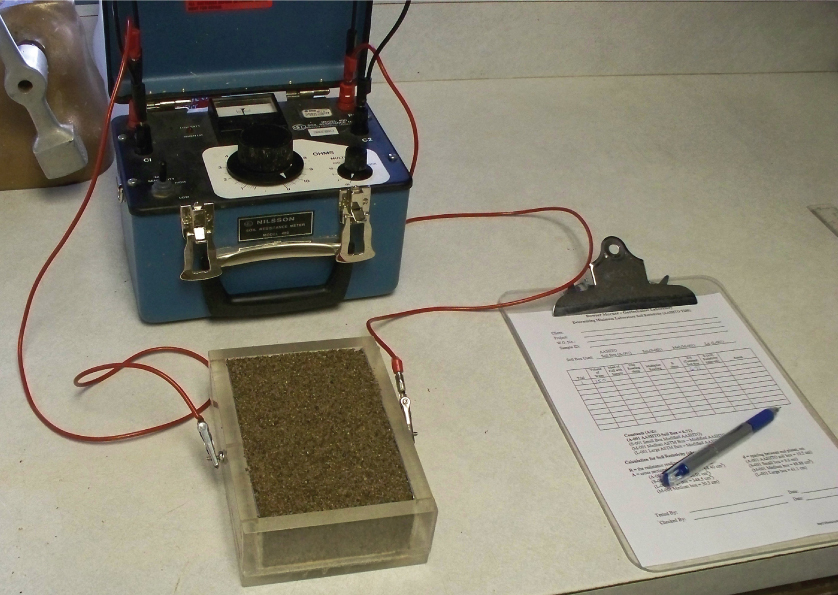

AASHTO has adopted Method T 288 for measuring resistivity after review and analysis of a number of available methodologies. T 288 requires preparing and drying a soil sample, adding 150 ml of distilled water, hand-compacting the sample into the test box (Figure 1), then measuring the resistivity.

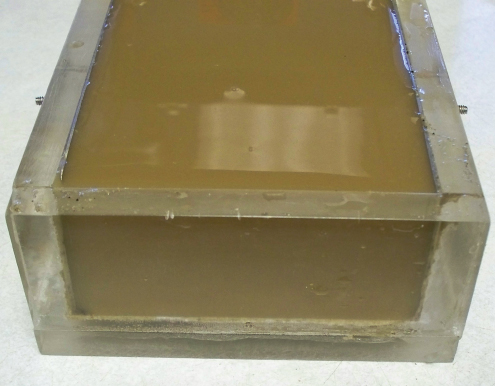

The soil is removed from the box and an additional 100 ml of water is added. The sample is put back in the box, first pouring in any free water, then as much of the soil solids as will fit in the box without water flowing over the top. Again measure the resistivity. Repeat these steps until the minimum value is determined. When following T 288-12, Note 6 (Note 5 in older editions), minimum resistivity often occurs when the soil is in a slurry (supersaturated) state and the test box looks like Figure 2, with little or no soil in the box.

AASHTO T 288 Test Must Stop at 100% Saturation

The resistivity of water is not relevant to MSE structures because MSE structures are backfilled with actual soil, which cannot exist in the field at more than 100% saturation. When the soil in an MSE wall is in a compacted state, with all the voids filled with water, we have 100% saturation and the resistivity at this condition is the minimum resistivity applicable to the design of MSE structures. The corrosion loss rates in AASHTO are based on the resistivity of soil at 100% saturation, so to properly design an MSE wall with steel reinforcements, we must confirm the resistivity of the soil at 100% saturation is greater than 3000 ohm-cm.

This requirement is spelled out by the National Highway Institute in its Publication No. FHWA-NHI-09-087, Corrosion/Degradation of Soil Reinforcements for Mechanically Stabilized Earth Walls and Reinforced Soil Slopes, which states:

“Resistivity should be determined under the most adverse condition (saturated state) in order to obtain a comparable resistivity that is independent of seasonal and other variations in soil moisture content. AASHTO has adopted Method T-288 for measuring resistivity after review and analysis of a number of available methodologies. This laboratory test measures resistivity of a soil at various moisture contents up to saturation [emphasis added] and reports the minimum obtained resistivity.”

How to Run the AASHTO T 288 Test to 100% Saturation

To measure MSE backfill resistivity at 100% saturation, conduct the T 288 test procedure through the first cycle of adding 150 ml of water, compacting the soil sample in the test box and taking the initial resistivity measurement. For subsequent cycles of the test:

- Do not remove the soil from the test box.

- Add water in increments of 50 ml per cycle.

- Allow time for the water to flow into the soil voids.

- Measure the resistivity after each addition of water.

- 100% saturation has been achieved when a sheen (as shown in Figure 3) is observed on the top of the test sample. This sheen may occur after only one or two additions of water beyond the first 150 ml.

- Alternatively, determine the amount of water needed to reach saturation using standard geotechnical laboratory procedures, and add this amount of water in 50 ml increments as described above.

The Importance of Correctly Testing Resistivity

Structurally – and electrochemically – acceptable backfills may be rejected for use in MSE structures simply because the resistivity test is being performed on a sample in a slurry (supersaturated) state and the result is less than 3000 ohm-cm. However, MSE structures are constructed of solids, not slurry, and saturation is the highest possible water content in actual MSE structures. Therefore, to prevent resistivity-based rejection of perfectly acceptable MSE backfills, the T 288 test should be conducted up to 100% saturation (not to supersaturation) and the resistivity measured at 100% saturation should be reported as the minimum resistivity of the soil.

Special thanks to Karl Fletcher, Manager Construction Materials and Geotechnical Laboratories, of Bowser-Morner in Dayton, OH, for use of the above photographs.

Tap to Call

Tap to Call Tap to Email

Tap to Email