Stray Currents from Commuter Rail Systems are not a Concern for MSE Walls with Discrete Steel Soil Reinforcement

What are stray currents?

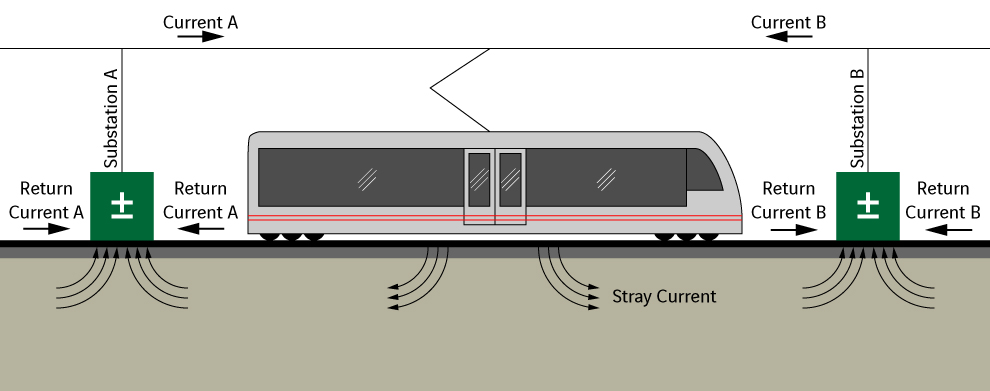

Stray currents can develop around electrified railway tracks powered by direct current. The rails serve as conductors for the return of current from a train to the substations. When the rail is not perfectly insulated from the ground, some of the current can discharge or “stray” into the soil below. Depending on the intensity of the current and the conductivity of the ground, stray currents can influence the corrosion rate of some metallic objects adjacent to and beneath the tracks.

Why is the use of MSE walls in the vicinity of electrified rail sometimes scrutinized?

Reinforced Earth MSE walls have been used for direct support of electrified rail since the early 1970’s on five continents, and in the United States since 1977. This includes public transportation systems in Atlanta, Boston, Charlotte, Dallas, Denver, Los Angeles, Miami, Philadelphia, Portland, Sacramento, Seattle, and Washington, D.C.

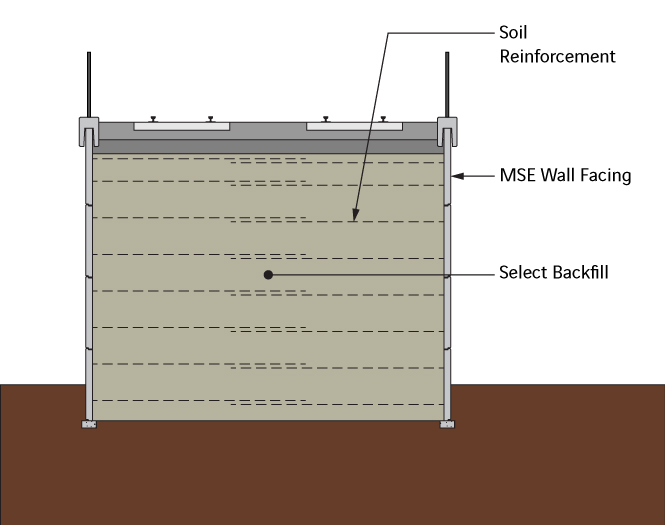

MSE walls are built using select backfill, soil reinforcements, and facing. Soil reinforcements for large structures and public transportation projects are often galvanized steel, in the form of discrete strips or welded bar mats. The design of MSE walls include a service life that is partially determined by the corrosion rate of the galvanized steel soil reinforcements buried in the backfill, which is carefully tested to ensure that it adheres to a list of specifications including electrochemical guidelines. In the early days of modern MSE walls, a question was raised as to whether commuter rail stray currents might increase the corrosion rate of MSE wall soil reinforcements, thus reducing the expected service life of the structure.

What was the verdict?

After comprehensive review by corrosion experts, galvanized steel reinforcing strips have continued to be recommended for use in retaining structures in conjunction with direct current traction powered rail systems worldwide. These structures include walls adjacent to and supporting railway lines.

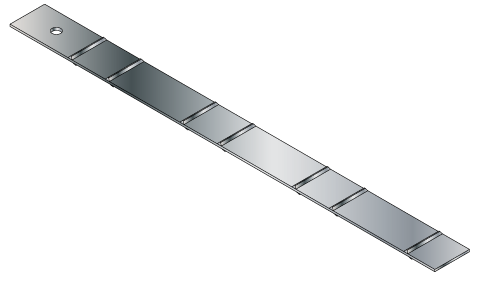

Stray currents do not cause increased corrosion in a galvanized steel strip reinforced MSE structure because the discrete metallic reinforcement in the wall system lacks electrical continuity. The reinforcements act as individual short length conductors rather than part of a network. This means that there is no tendency for stray currents to collect, accumulate and discharge to the earth at remote locations.

Evidence against corrosion from stray current development in steel-reinforced MSE walls was presented in a 1999 publication (Volume 1675, Issue 1) of the Transportation Research Record, the Journal of the Transportation Research Board (TRB). The publication included a technical paper titled, the Effects of Stray Currents on Performance of Metallic Reinforcements in Reinforced Earth Structures (John E. Sankey and Peter L. Anderson).

The paper provides a background of corrosion considerations for Reinforced Earth MSE walls and how stray currents are transferred through the MSE wall volume from a rail transit system.

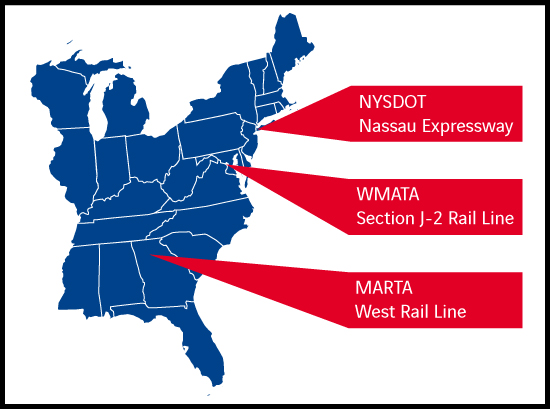

The authors go on to summarize three independent field investigations conducted on Reinforced Earth MSE walls by corrosion experts:

- MARTA West Rail Line, 1975 – Federal Highway Administration (FHWA)

- WMATA Section J-2 Rail Line, 1983 – Professional Services Group, Inc. (PSG)

- NYSDOT Nassau Expressway Bridge Abutments, 1988 – PSG & Corrosion Testing Laboratories, Inc.

All three studies concluded that stray currents are not a concern for MSE walls constructed with discrete galvanized steel soil reinforcements, based on these major factors:

- The individual discrete reinforcing strips are very short in comparison to the rail tracks and to other metallic structures generally adjacent to the railway.

- The reinforcements in the soil are electrically discontinuous.

- Reinforcing strips are generally placed perpendicular to the direction of the running rails and the return current flow.

- The high resistivity of the select granular backfill used for MSE walls reduces the tendency for stray currents to flow within the MSE volume, as opposed to the less resistant rails, adjacent metallic utilities and the in‐situ soils.

The conclusions and project references are specific to Reinforced Earth MSE walls constructed with RECo’s ribbed galvanized steel reinforcing strips.

Moving forward:

Worldwide, railway administrations and their corrosion consultants have recommended the use of MSE walls with galvanized steel reinforcements for such applications primarily because they have concluded that stray current corrosion has a negligible effect on the service life of the structure.

For example, AASHTO bridge design codes adopted the basis for steel-reinforced MSE walls specifically from the TRB publication:

Excerpt from the 2012 AASHTO LRFD Bridge Design Specifications:

11.10 – Mechanically Stabilized Earth Walls

C11.10.1

“All available data indicates that corrosion in MSE walls is not accelerated by stray currents from electric rail lines due to the discontinuity of the earth reinforcements in a direction parallel to the source of the stray current. Where metallic reinforcements are used in areas of anticipated stray currents within 200 ft of the structure, and the metallic reinforcements are continuously connected in a direction parallel to the source of stray currents, a corrosion expert should evaluate the potential need for corrosion control requirements. More detailed information on stray current corrosion issues is provided by Sankey and Anderson (1999).”

Since discrete steel MSE reinforcing strips are not continuously connected in a direction parallel to the source of stray currents, additional corrosion control methods are unnecessary. If the MSE wall supplier and builder follows standard practice for design, materials, construction, and drainage measures, there is no concern that stray currents from commuter rail systems will have a negative influence on the corrosion of discrete steel soil reinforcements.

Tap to Call

Tap to Call Tap to Email

Tap to Email