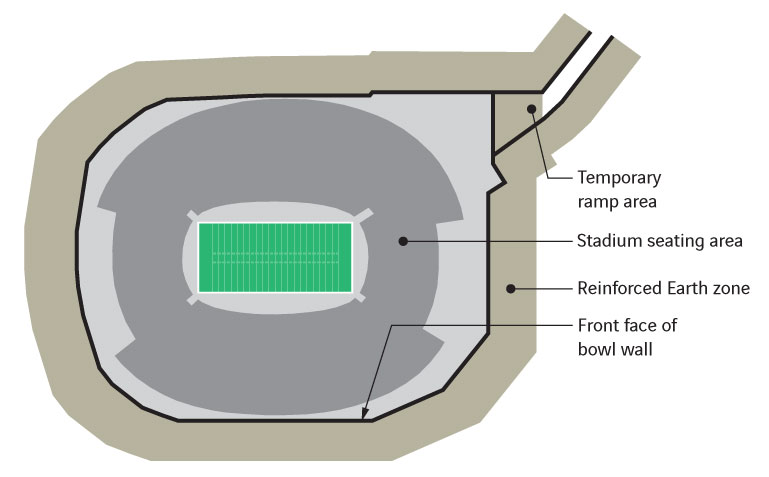

Sofi Stadium in Inglewood, California, is home to National Football League (NFL) Los Angeles Rams and Los Angeles Chargers. It is one of the biggest stadiums used by the NFL. It also has one of the tallest mechanically stabilized earth (MSE) walls in the world that stands 100 feet tall. RECo installed the Reinforced Earth® wall as a stress relief around the stadium footprint, forming a “bowl” for the main structure to be set below the original grade.

If built on existing grade, the stadium would have invaded the nearby navigational airspace of the Los Angeles International Airport. To keep the final stadium elevation below the limitation, it had to be set approximately 100 feet into the existing grade. The project team’s initial designs for top-down retaining wall construction did not prove to be a viable solution when considering the extreme height, seismic criteria, and project schedule. To move the project along as fast as possible and to begin stadium foundations at the earliest date possible, the contractor decided the best option was to excavate the 100-ft deep hole, then build a wall up concurrently with the stadium structure inside the bowl.

Due to high seismic considerations in the Los Angeles area, it was necessary to design a bowl wall that would alleviate potential dynamic forces from the stadium structure. Reinforced Earth MSE walls are highly flexible and can be designed to accommodate the most extreme seismic criteria. RECo’s engineering team was able to provide the contractor with a design that worked, and gained approval from the reviewers relatively quickly.

Ultimately, the most beneficial aspect of the Reinforced Earth wall was the construction schedule. Overall, the wall was topped out in about a year and a half. The constructability of the wall system allowed the contractor to maximize their schedule, and gave them the flexibility to build out of sequence and accommodate other design changes quickly. The MSE wall design saved the contractor millions of dollars and about a year of construction time.

“…the MSE wall provided the project with significant schedule advantages.” – Kiewit

Most of the MSE wall at the SoFi stadium was built using concrete-facing panels. Over 300,000 square feet of concrete and wire mesh were used to construct the wall. This is the equivalent of nearly five football fields worth of materials.

Wire mesh facing TerraTrel panels were used in areas for temporary ramps down to the bottom of the excavation area and to support fill behind other stadium features within the reinforced soil volume. Ribbed steel strips were used for soil reinforcement for the entire Reinforced Earth wall. Up to 13 soil reinforcements were connected to one 5-foot x 5-foot concrete facing panel.

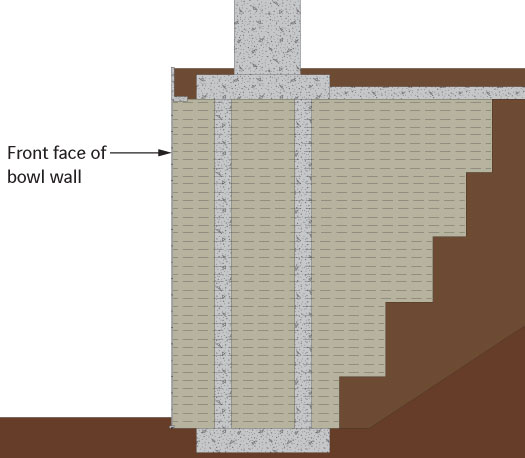

Over 5,000 miles of reinforcing strip lengths of up to 120 feet were used. Most of the wall was designed with a trapezoidal cross-section, meaning lower portions of the wall required shorter soil reinforcements with the length increasing in sections higher up the wall. The design optimized the length of soil reinforcements and select backfill quantity. The tallest portions of the wall used reinforcing strips of six different sizes.

Over 1,500 miles of reinforcing strips were installed – the same distance the L.A. Rams traveled when they moved from St. Louis to Los Angeles.

Staying out of LAX airspace and the project schedule were only a few challenges the construction team faced when deciding on an MSE wall. Additional challenges included the stadium’s weight which needed to be held up.

Various foundations for the stadium structure were located behind the wall facing inside the MSE wall reinforced earth volume. Within its fill, the wall had to withstand loads for the roof, stairs, upper-level structures and more. Hundreds of foundations were located within the backfill, including piles, shafts and footings. The largest of the foundations was for the roof. The foundations were accommodated by skewing reinforcing strips, placing additional reinforcing strips and adding wire-faced relief walls adjacent to the obstructions to alleviate earth pressure on them.

All of the stadium’s foundations and structures within the MSE volume had to be categorized as “moving with the wall mass” or not. Many items were isolated from the MSE wall by using additional facing and soil reinforcements. For example, a tunnel for VIP and player access was installed through the reinforced soil by building permanent wire-faced MSE walls along the concrete tunnel. This isolated the tunnel from the MSE wall volume.

In one section, a third-floor restaurant required a foundation on piles. The first row of piles was close to the back of the MSE wall, requiring careful calculations that factored in the lateral loads imposed on the wall at each location. RECo’s engineers drew out the influence zones for each pile and added the loading to the earth pressures in the internal stability calculations of the wall.

A 10.5-foot tall cast-in-place cantilever wall was incorporated along the entire top of the main bowl MSE wall. This allows stadium management teams to easily access the utilities and other maintenance areas without calculating where the MSE wall’s reinforcing strip is.

A TerraTrel™ wire-faced MSE wall system was also used for various applications on the project. This system is made of high-adherence steel that is inextensible and an affordable, temporary solution that is ideally suited for areas that cannot handle heavy lifting. For this project, the temporary TerraTrel wall was built to provide access to the bottom of the excavation and eventually buried when the ramp was closed off with a section of permanent MSE wall.

In general, all of the stadium’s foundations and structures within the MSE volume had to be categorized as “moving with the wall mass” or not. Many of the items were isolated from the MSE volume using additional facing and soil reinforcements. For example, a tunnel for VIP and player access was installed through the reinforced soil volume. Permanent wire-faced MSE walls were built along the concrete tunnel to isolate it from the MSE volume.

Using an MSE wall enabled the contractors to overcome numerous challenges the construction of the SoFi Stadium presented them. This is due to the unique benefits of an MSE wall, such as its versatility and ability to carry extreme weights.

The MSE wall at SoFi stadium ensured the contracting team could complete the job on time and within the limitations because of the following:

RECo is proud to have played a role with Kiewit and the rest of the project team in constructing the Rams’ and Chargers’ new stadium. Our world-class MSE walls have been used in over 45,000 structures across the United States since 1971 and are the first choice for many large-scale construction projects. See more about the construction of the wall and entire stadium on The Science Channel and contact us to learn more about our products today.